Project Information

DI Valentin Tschikof

BM DI Eugen Keler

Martin Rümmele

Erwin Scheuhammer, BSc Arch

Bmst. Gerold Hämmerle

Zinner Ingenieure GbR, Krailling

Builder-Owner

Isar - Würm - Lech IWL GmbH Werkstätte für Menschen mit Behinderung, Landsberg am Lech

Location

Landsberg

Completition

2013

Project facts

n.b.ar. 7832 m², GFA 8480 m²,

GBV 42981 m³

Energy

47,4 kWh/m²a - primary energy requirement 29,5 kWh/m²a

Project Phases

Competition

Implementaion

Rights

Text Hermann Kaufmann + Partner ZT GmbH,

Translation Bronwen Rolls

Photo

Matthias Kestl

- Structural Engineering Timber Construction

merz kley partner ZT GmbH, Dornbirn - Structural Engineering Concreate Construction

merz kley partner ZT GmbH, Dornbirn - Heating Ventilation and Sanitary Planning

Ingenieurbüro Hausladen Gmbh, Kirchheim - Electronics Planning

Veit Energie Consult GmbH, München - Akustik

Müller - BBM GmbH, München - Building Physics

Ingenieurbüro Hausladen Gmbh, Kirchheim

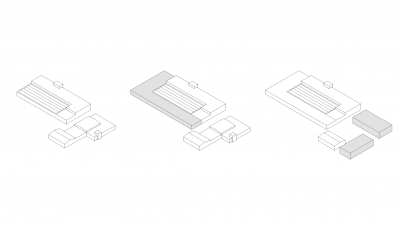

Isar-Würm-Lech GmbH, Landsberg am Lech

The carpentry workshop, the administrative depart, and a new power supply has been rebuilt to the west of the existing structures. Between the new building and the existing building, a pedestrianised zone is created, to avoid a clash between the flow of goods and the flow of people. The main idea for the final area is the creation of a spacious multi-functional ‘village square’. This area serves as a large meeting and socialising zone, which accommodates various functions. On the southern boundary of the property, a quiet park is created, which offers a different quality of atmosphere than the ‘village square’. This creates a differentiated environment within the overall development.

»During the planning and implementation process, special attention was paid to resource-saving. All innovative components, building materials, construction methods and technical building equipment had to meet the criteria of sustainability and resource conservation. To achieve this goal an integrated planning process was adopted, creating a holistic approach to planned sustainability«

Univ.-Prof. Arch. DI Hermann Kaufmann

The new IWL stands out because it’s unique in comparison to the usual commercial buildings. The overall design is subject to pragmatic criteria such as functionality and constructive limitations, but what makes this project distinctive is the consistent application of the renewable building material, wood.

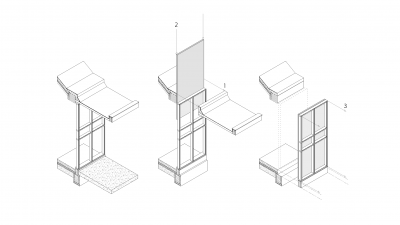

The IWL signifies resource-saving and the power of extraordinary design in timber. It highlights the effect on quality of room design and atmospheric qualities this material has. The largely natural wood application takes into account the weathering process, the facades are designed in such a way that the sensitive window areas are protected by canopies or they are shielded by being embedded in the façade itself.

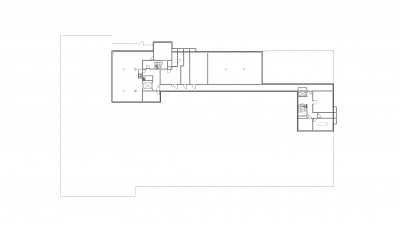

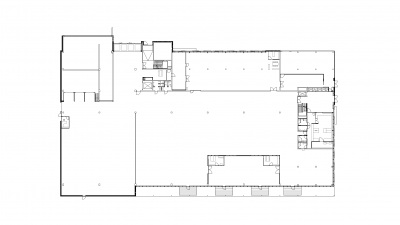

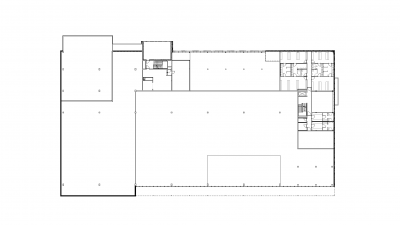

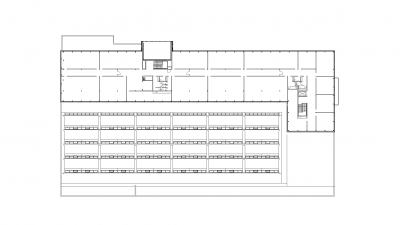

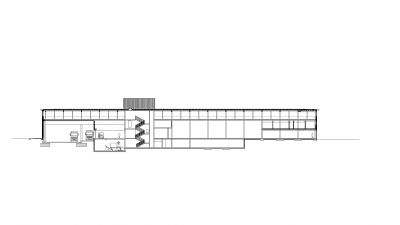

The entire workshop area is designed to be as flexible as possible. The necessary cores functions of the workshop are located on the peripheral areas, so as not to impede on further development. A connection to the new cafeteria, administration and seminar building is from a mezzanine level via a bridge, allowing for all the zones to be connected, while maintaining independence from each other. The production building is situated on the east side of the village square, with its own delivery zone. The existing workshop and cafeteria buildings are to be reused as generic functional working areas.

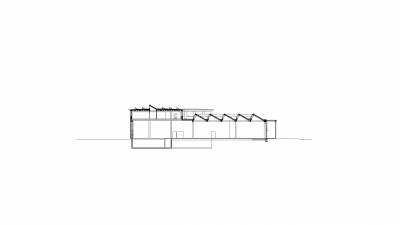

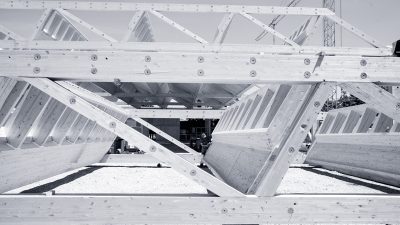

The workshop building is built using a mixture construction method, both timber and concreate. A large concreate footprint base layer is created. From this level, concreate pillars rise up to create an additional level, with a concreate ceiling. The additional space above the concreate footprint is double height, and with a wooden ceiling. The second floor is built entirely in wood, as well as the cafeteria administration building. Over the cafeteria area there is a concrete ceiling, the remaining two floors are designed using timber construction. Natural wood is the main material both outdoors and indoors. The colour accentuation of individual areas is very discreet.

The hybrid timber construction is a good basis for achieving the goals of energy-efficient construction. Particular attention is paid to the use materials that have no negative health impacts on the buildings users. All material decisions are subject to these criteria. The uses of durable materials in the building structure, allows flexibility, and guarantees low life-cycle costs. Likewise, all technical equipment and cabling remain accessible, to ensure ease of use when there are slight changes or maintenance required. Compact structures in conjunction with optimised building envelopes enable a reasonable energy concept; a passive house quality.

The compact design of the building ensures minimised energy consumption with an optimised building envelope and high levels of daylight utilisation. To generate heat, the wood remnants are salvaged and used. For the hot water preparation, the waste heat of the compressed air generation is used. The heat transfer in the production and storage areas is carried out by radiant ceiling panels. The shed roofs serve, on the one hand, as a ventilation option and on the other, as a mounting surface for the photovoltaic modules. The new administration building is equipped with a ventilation system with heat recovery in the canteen and in the seminar rooms. By using a geothermal heat exchanger, the supply air is preconditioned.

Projektpläne

Bausfotos

Public

- Holzwerkstätten in Landsberg

ZN Z-297, Louis, 01/2015, S. 14-25