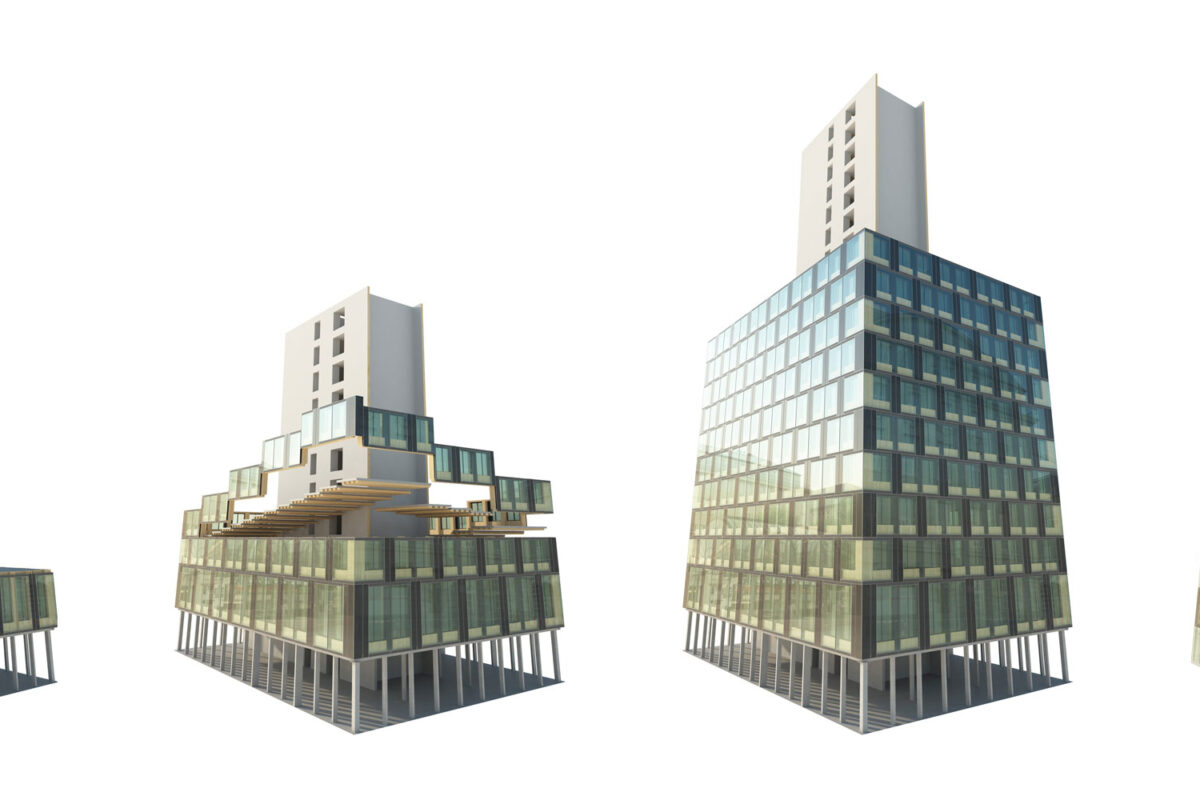

LCT ONE the world’s first multi-storey hybrid timber passive house building with a modular construction system.

The LCT ONE is the first ever multi-storey building made using timber. The LCT ONE is a prototype of prefabricated timber construction, developed for the research project “LifeCycle Tower”. This research project consists of experts in architecture, structural engineering, building engineering, technology and process management who are working collectively to develop a solution for sustainable urban development. Their detailed and in-depth work proves that timber construction could do a lot more than previously thought.

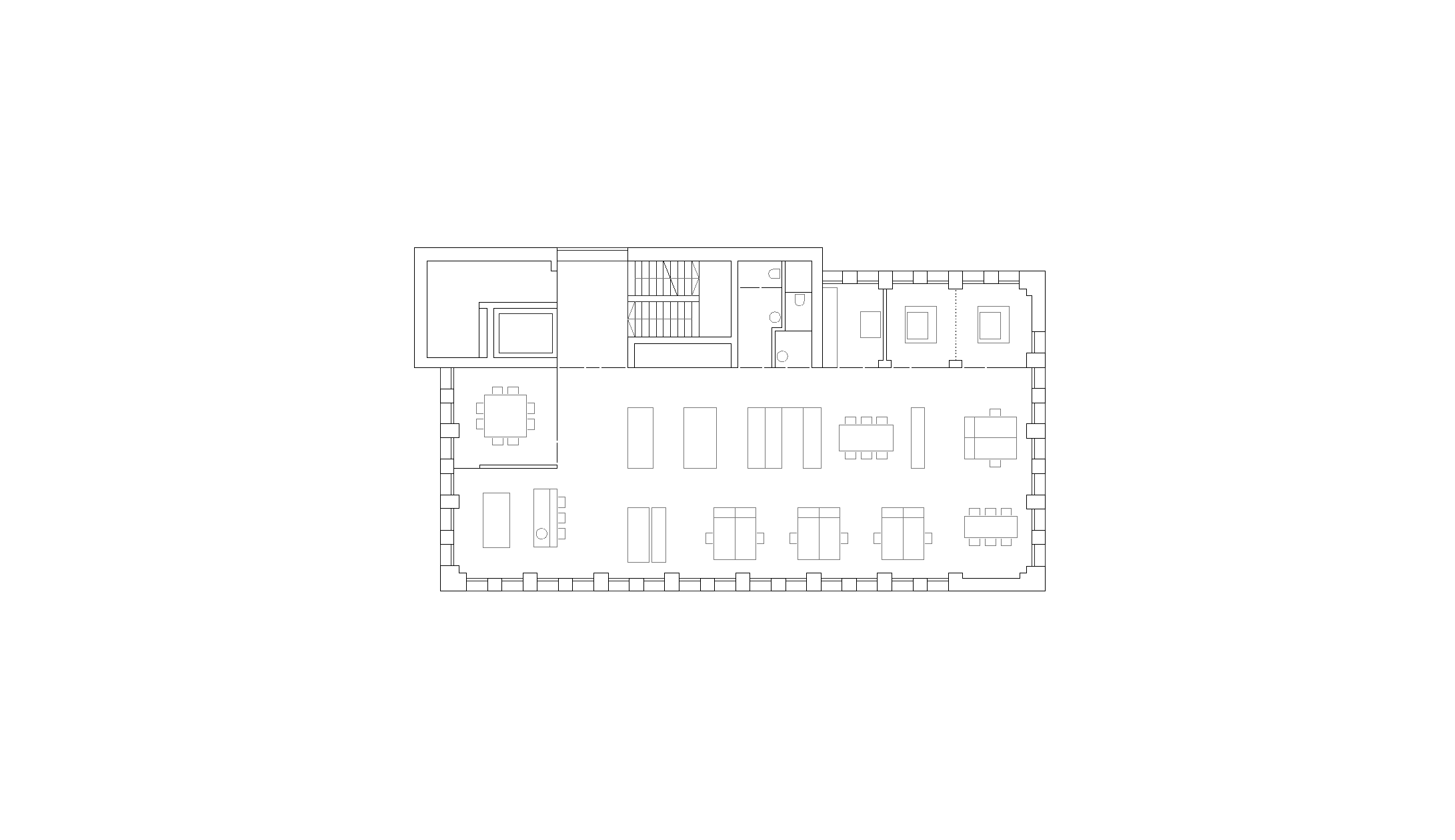

The aim of the project is to verify the feasibility of the construction system, and to declare it both functional and efficient through use. This modular prefabricated construction system will be marketed internationally, making the LCT ONE pilot project a central building block for both testing and future marketing success.

Read more

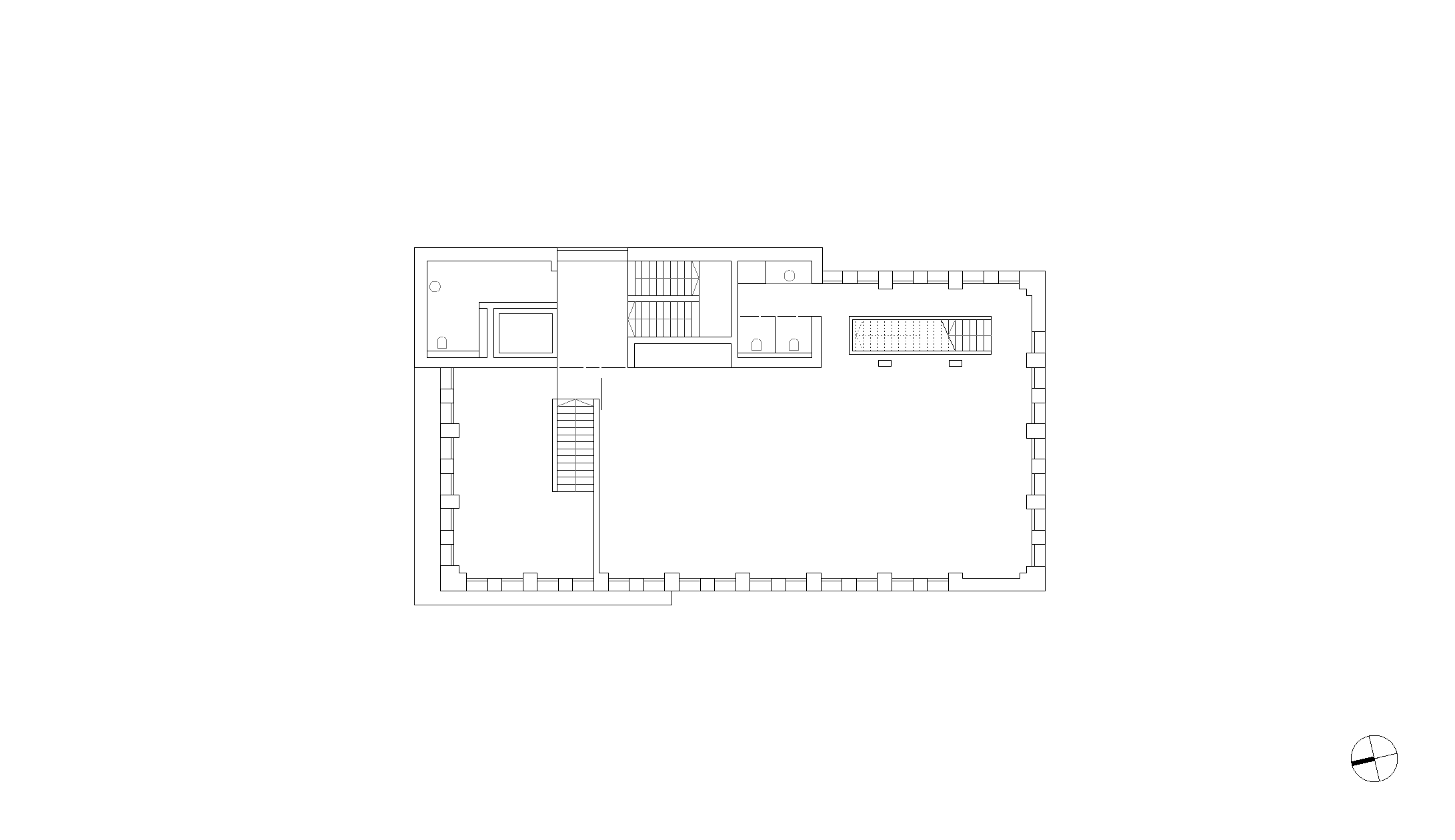

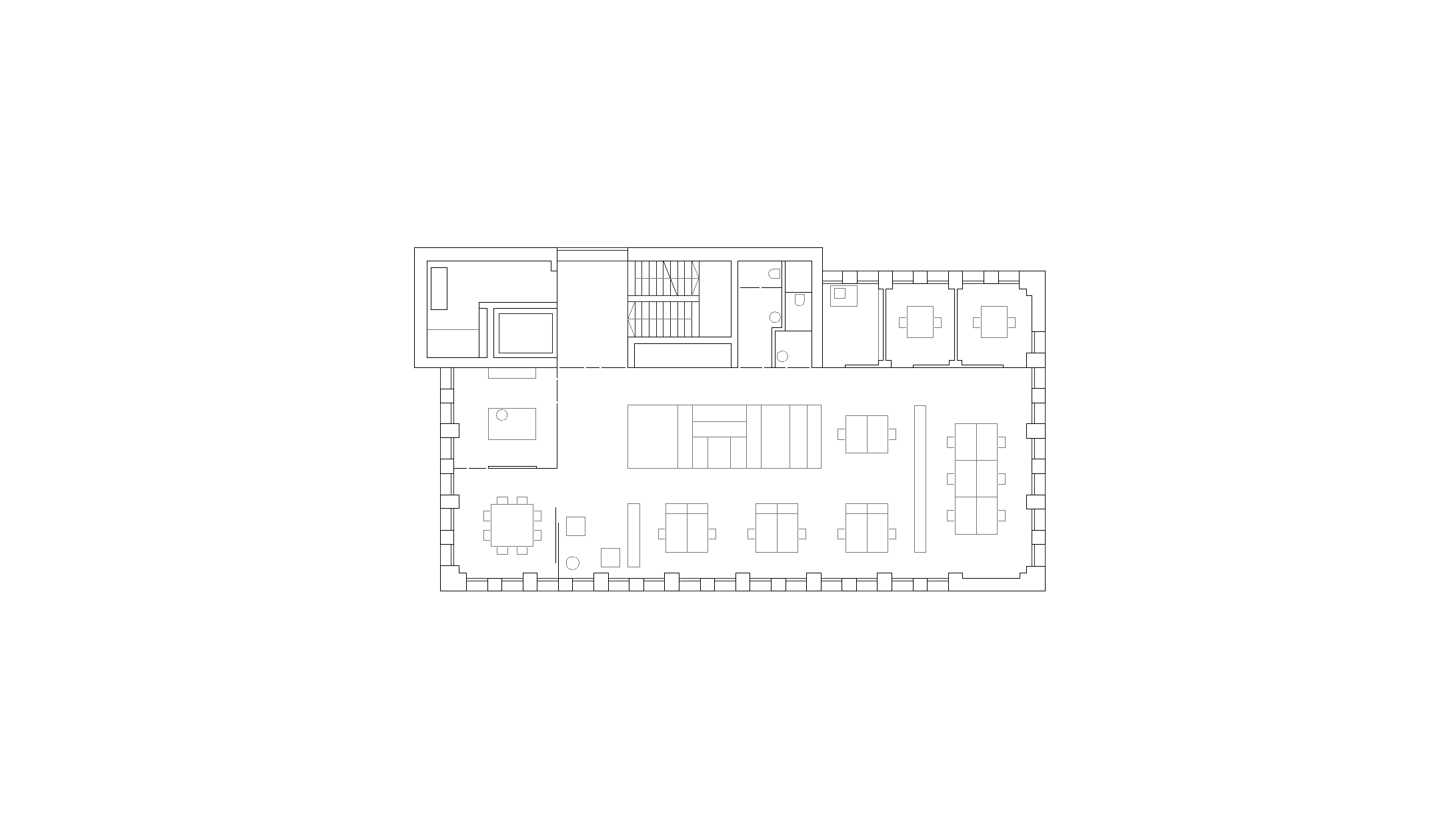

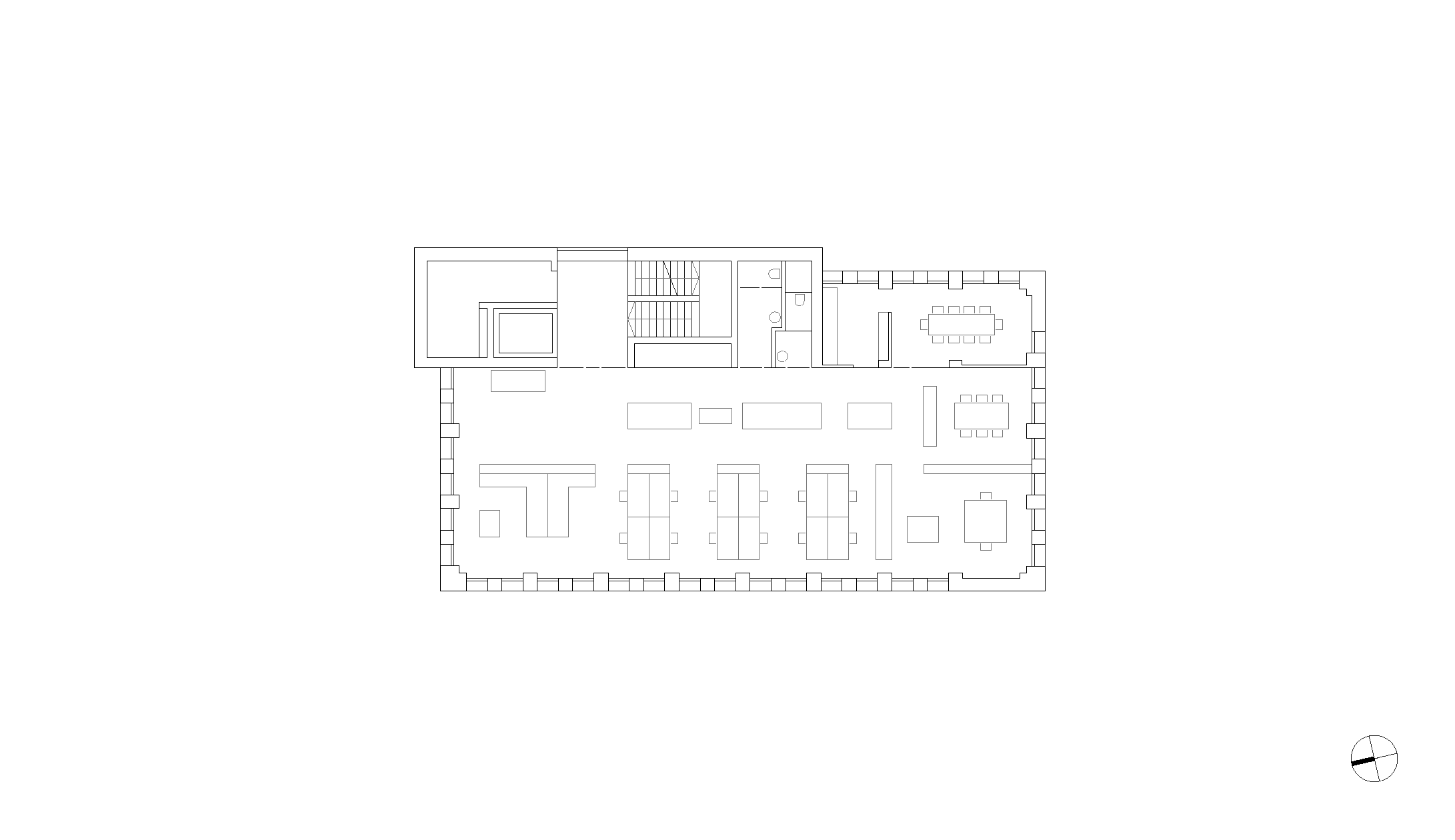

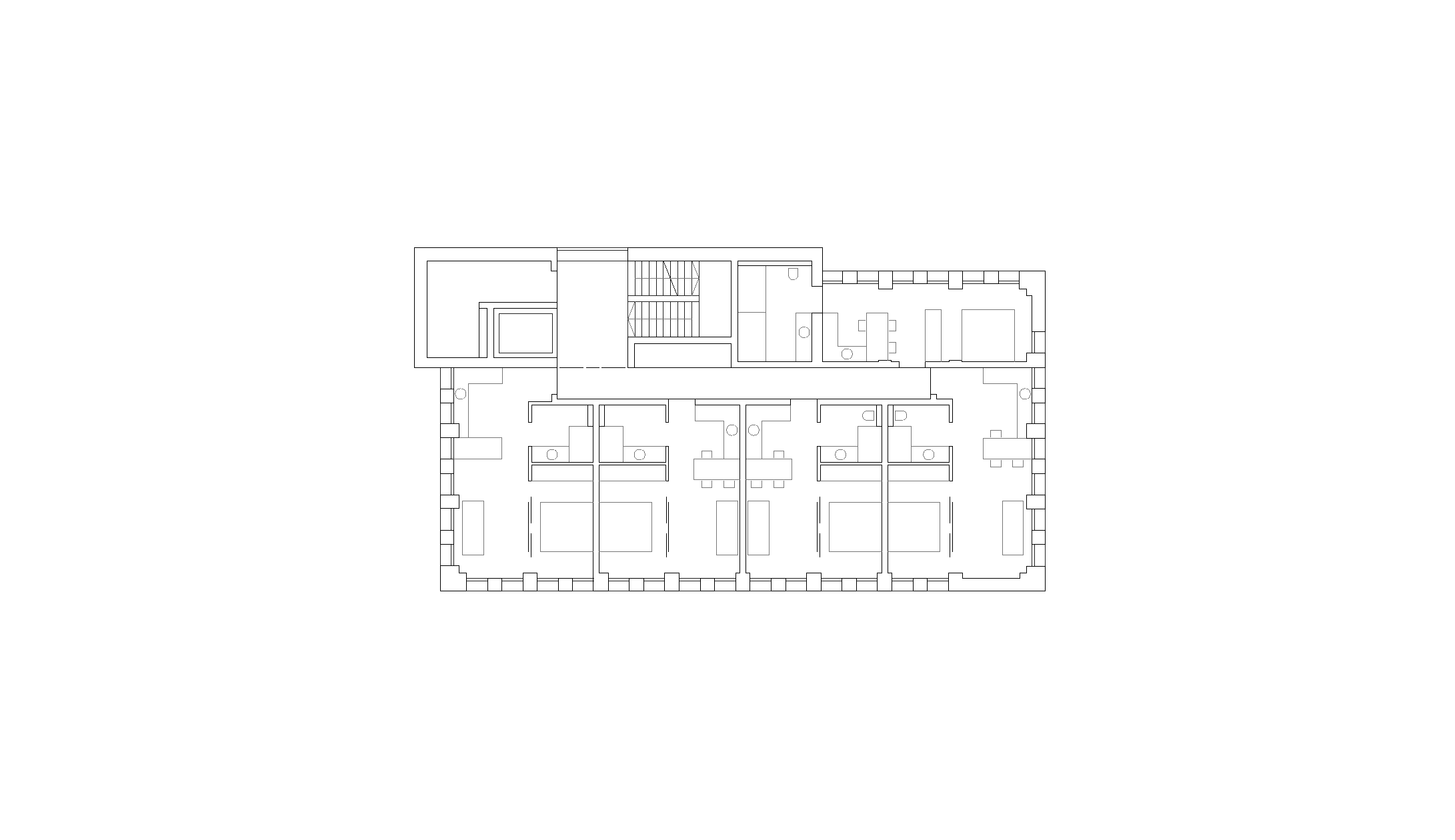

The building consists of a reinforced staircase core, bordering on one-side to the office space. Contrary to the original proposal to build the staircase core in wood, statutory provisions of fire prevention meant that the staircase had to be made in concrete.

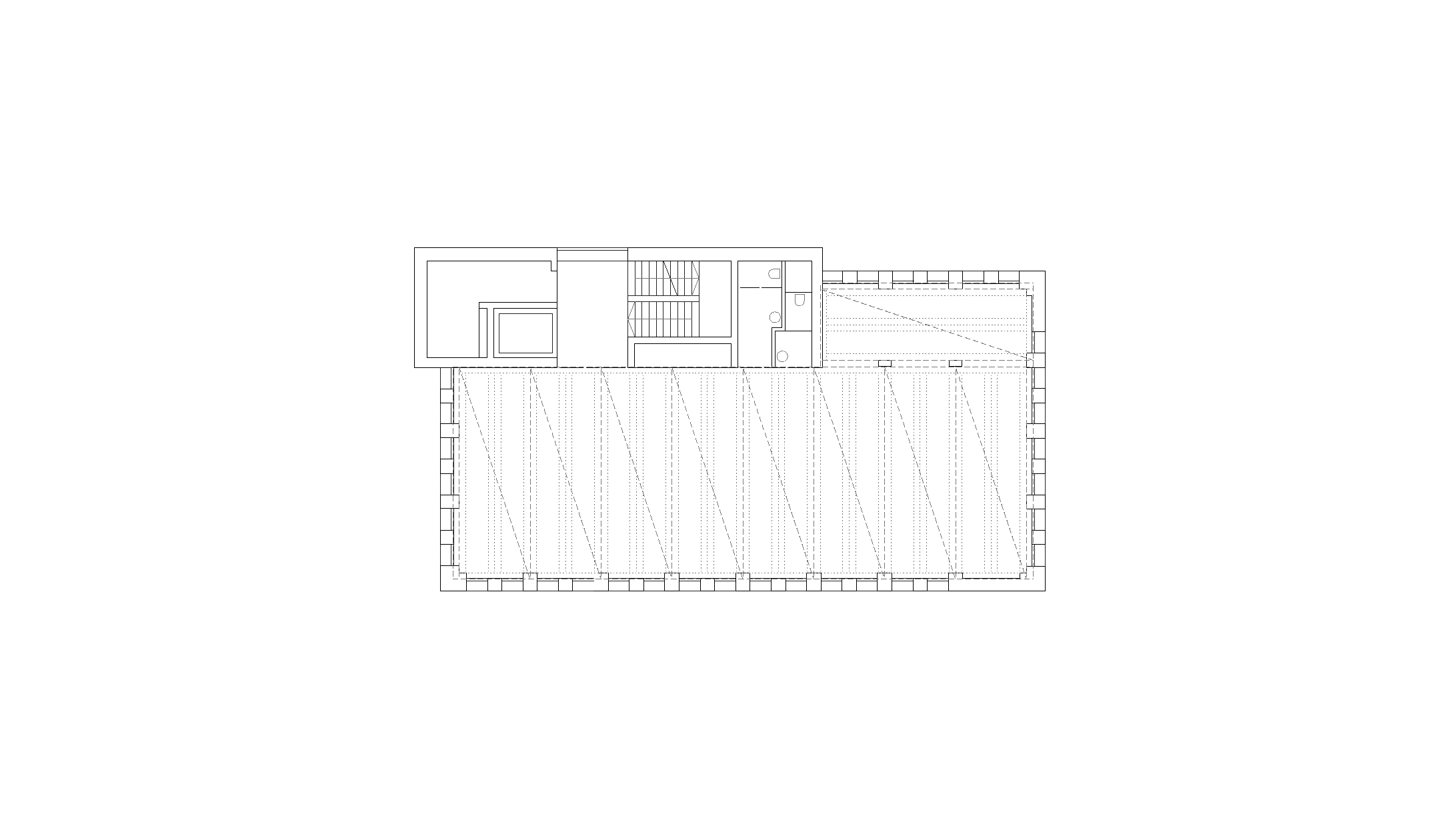

LCT ONE has certification (according to DIN EN 13501) of the fire resistance REI 90 for the timber joint hybrid ceiling. To achieve this several timber joint elements were subject to fire testing. Receiving this fire resistance certification was an important step towards the realisation of the building.

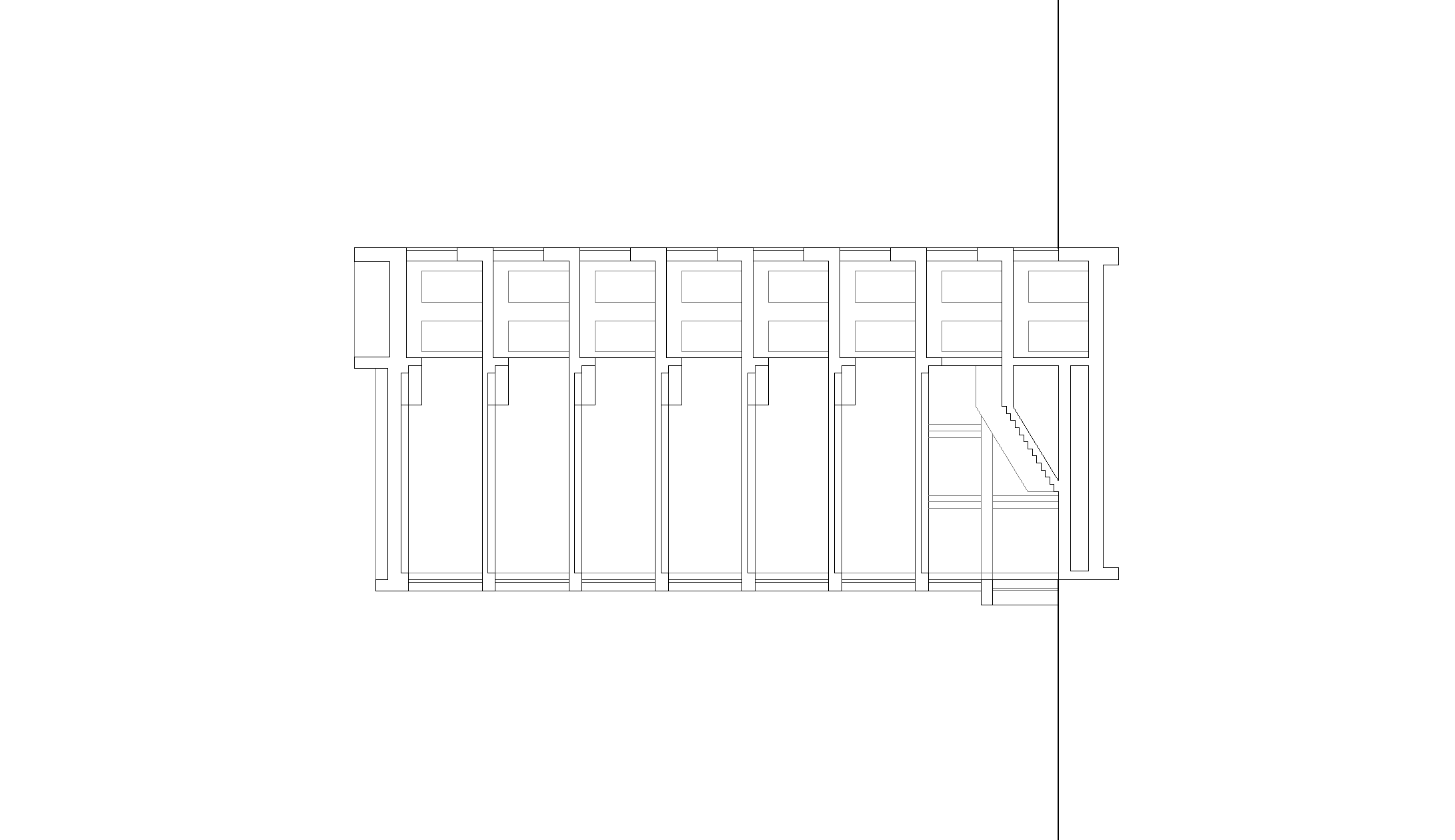

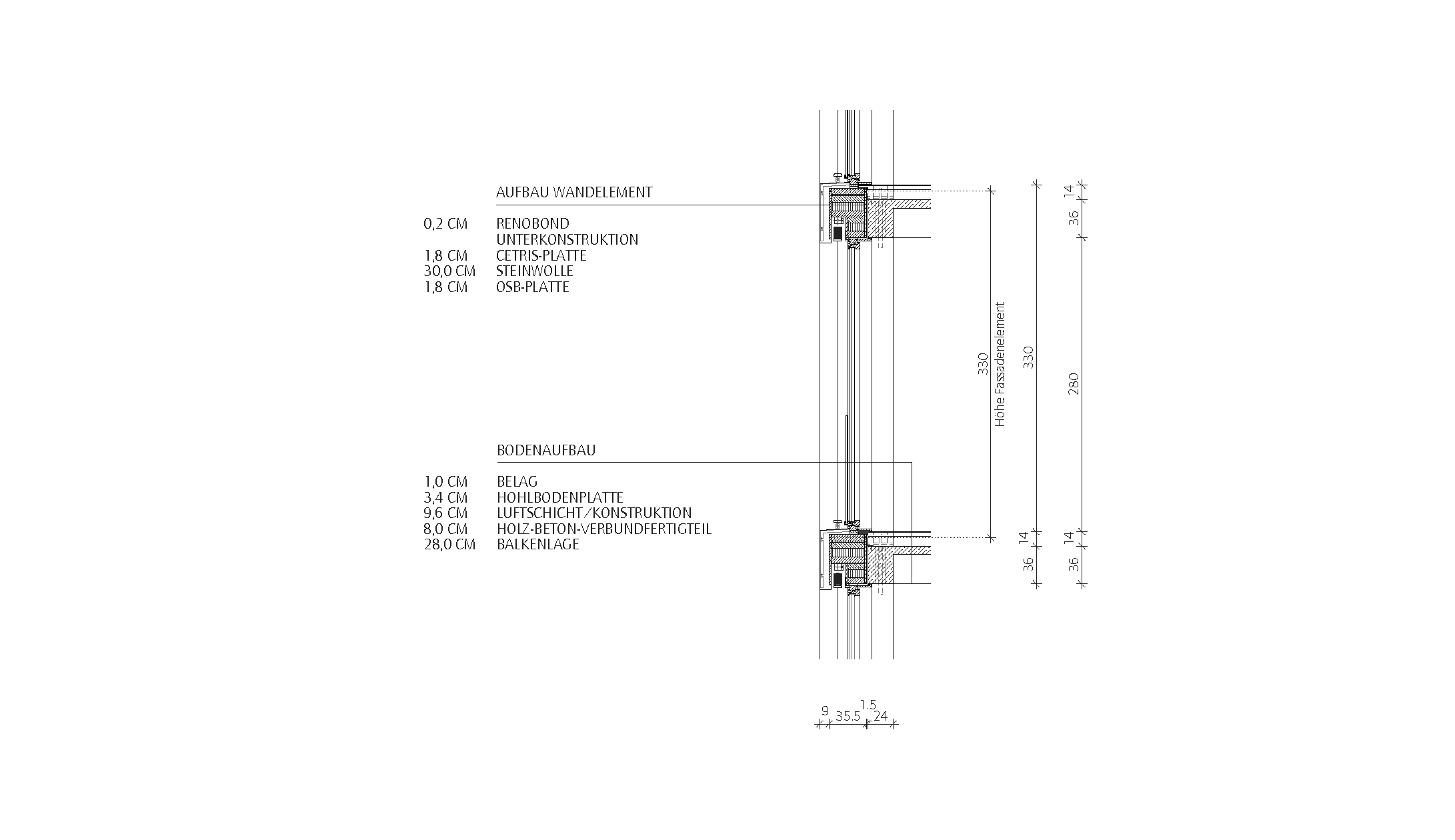

The timber-concrete joint ribbed ceilings are the real key for being able to build upwards. The ceilings make it possible to separate the corresponding floors with a non-combustible cover. The wooden beams are inlaid into a steel formwork of 8.1 x 2.7 meters; the distances in between are formed and concreted using a grouting technique. Thanks to the high grade of pre-fabrication, the building process becomes much simpler. The ceiling elements can be made in a more precise manner; there are no curing times on site and the laying of a ceiling elements can take just 5 minutes.

The connection between concrete and laminated timber construction is not made via complicated binding agents, but rather with screws and notches. A lintel beam of concrete contributes considerably to the distribution of the enormous forces from the load bearing façade. The cross-grained wood of the double bearings stands directly on the concrete; the connecting arbour is grouted to the pre-fabricated segment on site. This lintel beam facilitates the necessary separation of the construction in terms of fire protection for every floor.